SMT

The heart of Mastertech’s Electronic production is the SMT (surface mount technology) department, where the entire surface is ESD Free (Electronic Static Discharge free) to avoid the accumulation of electrostatic charges dangerous for electronic systems.

The modern automatic assembly line, thanks to its high flexibility, allows us to easily deal with small series, such as large production batches.

THT

THT department (through-hole technology) completes Mastertech’s production chain together with the SMT department.

This technology, used until the eighties, has been gradually supplanted by the SMT one. Despite this, there are still a considerable amount of components that use the “through-hole” method, especially as regards the parts of the power interface (connectors, high capacity capacitors, transformers, etc …).

Also for this department, as for the SMT one, the materials and components used fully comply with EU directives regarding electronic production and the entire surface is ESD Free.

With a view to constantly improving our production processes, a selective welding machine Ersa Versaflow 4/55 has been introduced in our production line in order to standardize and improve our production processes, this machine also allows us to obtain a better precision and a reliable welding.

ICT

Despite the modern technologies, we are aware that there is the possibility of error within the production process. For this reason we have introduced a series of sophisticated controls to allow verification of the conformity of the process and the quality of the board assembly.

The ICT (In-circuit test) system composed of a SPEA 4080 is dedicated to this function for the verification of the assembly of components on PCB. During this process, short circuits, accuracy of the welds, values of the passive components (resistors, capacitors, inductances) and parameters of the active components (diodes, etc …) are checked.

The flying probe testing system allows these sophisticated checks implementation reducing investment costs if compared to other ICT methods (i.e. test-fixture) making all the benefits of this process available to small production lots.

Testing

The last steps before shipping always play a fundamental role in the process. For this reason, we pay great attention to the testing phase, that is, the set of operations implemented in order to verify the correct working of the product before it is destined for its purpose. For this reason, in the last years we have decided to invest economic resources to allow us to offer the customer a perfect product from every point of view.

To do this, we have bought an automatic optical inspection machine. With the help of the AOI we have the ability to check each single component and certify its correct positioning on the board

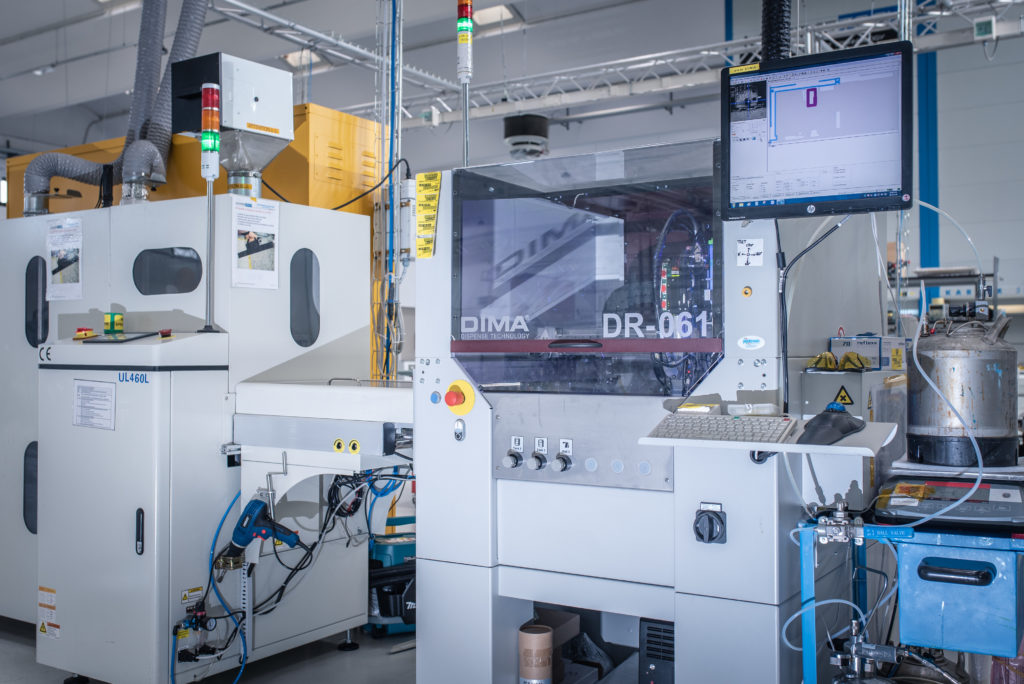

In recent years, the need has arisen to carry out more specific and precise checks. Precisely for this reason it was decided to introduce a machine for 3D AOI testing.

This advanced technology allows for accurate and detailed inspection of three-dimensional electronic components, identifying any defects or imperfections with surprising precision. Thanks to its ability to examine microscopic details and three-dimensional conformity, 3D AOI ensures the timely detection of defects that other inspection systems may miss. Choosing this cutting-edge technology is an important step towards optimizing production processes and creating reliable products that comply with the highest industry standards.

Once the testing process is finished, our boards can be painted through the conformal coating process which consists in coating the assembled pcb with a layer of resin that isolates the pcb. It protect the product from solvents, dust and humidity, improving the electrical insulation and avoiding the formation of oxides on the pcb.

The last control we have introduced is the X-ray inspection, thanks to the enormous power of this technology we are now able to check the internal parts of the components with very high precision, we also have the possibility to trace the factory defects on products. which, once finished, can no longer be disassembled

Last software uploading, user functions checking, climate tests and packaging preparation are only the last part of those procedures aimed at achieving that one goal that we have set ourselves since design: the quality of our products.